Powder Coat Curing Oven stands as the linchpin for attaining a truly immaculate powder - coated finish. This essential equipment comes in two primary types, each tailored to distinct user requirements and operational scales.

The entry - level tabletop

Powder Coat Curing Oven, with a starting price of around $400, is a boon for home - based crafters and those engaged in small - scale DIY projects. Its design is straightforward, featuring basic heating elements that are reliable and easy to understand. The manual temperature control allows users to have a hands - on approach to setting the heating parameters according to their specific needs. This simplicity makes it an ideal choice for hobbyists who are just dipping their toes into the world of powder coating and don't require highly complex features.

On the other hand, the professional - grade industrial

Powder Coat Curing Oven, starting at $6000, is engineered with large - scale manufacturing plants in mind. It incorporates advanced digital temperature control, which offers precise and consistent temperature regulation. The large - capacity chambers can accommodate a significant number of workpieces simultaneously, enhancing production efficiency. Moreover, the fast - heating technology ensures that the oven reaches the desired temperature in a short span, further streamlining the manufacturing process.

These ovens operate on a fundamental principle. They heat the powder - coated workpiece to a carefully determined specific temperature. As the temperature rises, the powder gradually melts and spreads evenly over the surface of the workpiece, eventually forming a smooth, durable layer that not only provides an aesthetically pleasing appearance but also offers excellent protection against corrosion and wear. To maximize energy efficiency and maintain a stable internal temperature, these ovens are constructed with high - quality insulation materials that effectively minimize heat loss. Additionally, most suppliers go the extra mile by providing installation services, ensuring that the oven is set up correctly for optimal performance. They also offer detailed user manuals that cover everything from basic operation to troubleshooting, and comprehensive after - sales technical support to address any issues that may arise during the oven's lifespan.

In the home decor handicraft industry, the tabletop oven proves to be an invaluable tool. It can be used to cure powder - coated metal decorations, allowing crafters to add a professional - looking finish to their creations. Whether it's a small - scale batch of custom - made wall art or unique metal - framed picture frames, the tabletop oven enables the application of a high - quality powder coat. In the large - scale metal furniture production, the industrial - grade oven plays a crucial role. It ensures that every piece of furniture, from massive dining tables to intricate metal chairs, receives a consistent and high - quality finish. This consistency is vital for maintaining brand reputation and customer satisfaction in the highly competitive furniture market.

Q: How do I preheat the Powder Coat Curing Oven?

A: First, locate the control panel of the oven. On it, you'll find the temperature - setting mechanism. Use the appropriate buttons or dials to set the desired preheating temperature. Once set, simply turn on the oven and let it run undisturbed for about 10 - 15 minutes. During this time, the oven will gradually heat up until it reaches the set temperature. You can monitor the progress through the temperature display on the control panel.

Q: What if the powder coating cracks after curing?

A: If you notice that the powder coating has cracked after curing, the first thing to do is to check the heating rate. A too - rapid increase in temperature can cause the powder to expand and contract unevenly, leading to cracks. Try to slow down the heating process, perhaps by reducing the power setting or increasing the preheating time. Additionally, ensure that both the powder and the workpiece are properly prepared. The powder should be free from contaminants, and the workpiece should be clean, dry, and free of any surface imperfections.

Q: Can I put different - sized workpieces in the same oven?

A: Yes, you can put different - sized workpieces in the same oven, provided that they all fit comfortably inside the oven chamber. However, it's crucial to arrange them in a way that they don't block the heat circulation. Uneven heat distribution due to blocked vents or crowded workpieces can result in inconsistent curing, so make sure there's enough space around each workpiece for the hot air to flow freely.

Q: How often should I calibrate the temperature control of the oven?

A: To ensure accurate temperature settings and consistent powder - coating results, it's recommended to calibrate the temperature control of the oven every 3 - 6 months. Regular calibration helps to account for any drift in the temperature sensors over time, ensuring that the oven heats to the exact temperature you set. There are specific calibration procedures provided in the user manual, which usually involve using a calibrated thermometer to measure the actual oven temperature and adjusting the control settings accordingly.

Q: How do I choose the right Powder Coat Curing Oven?

A: Selecting the right Powder Coat Curing Oven requires careful consideration of several factors. First and foremost, assess your production needs. If you're only involved in small - scale, occasional projects, such as creating powder - coated items for personal use or a few local customers, an entry - level oven with its basic features will likely suffice. However, if you're running a large - scale production operation, where high - volume output and consistent quality are essential, a professional - grade oven with its advanced features is a more suitable choice. Your budget also plays a significant role. The entry - level ovens are more cost - effective, making them accessible to hobbyists and small - scale entrepreneurs. In contrast, the professional - grade ovens, while more expensive, offer greater efficiency and precision, which can be well worth the investment for large - scale manufacturers. Additionally, take into account the size of your workpieces. Ensure that the oven you choose has a chamber size that can comfortably accommodate the largest items you plan to powder - coat.

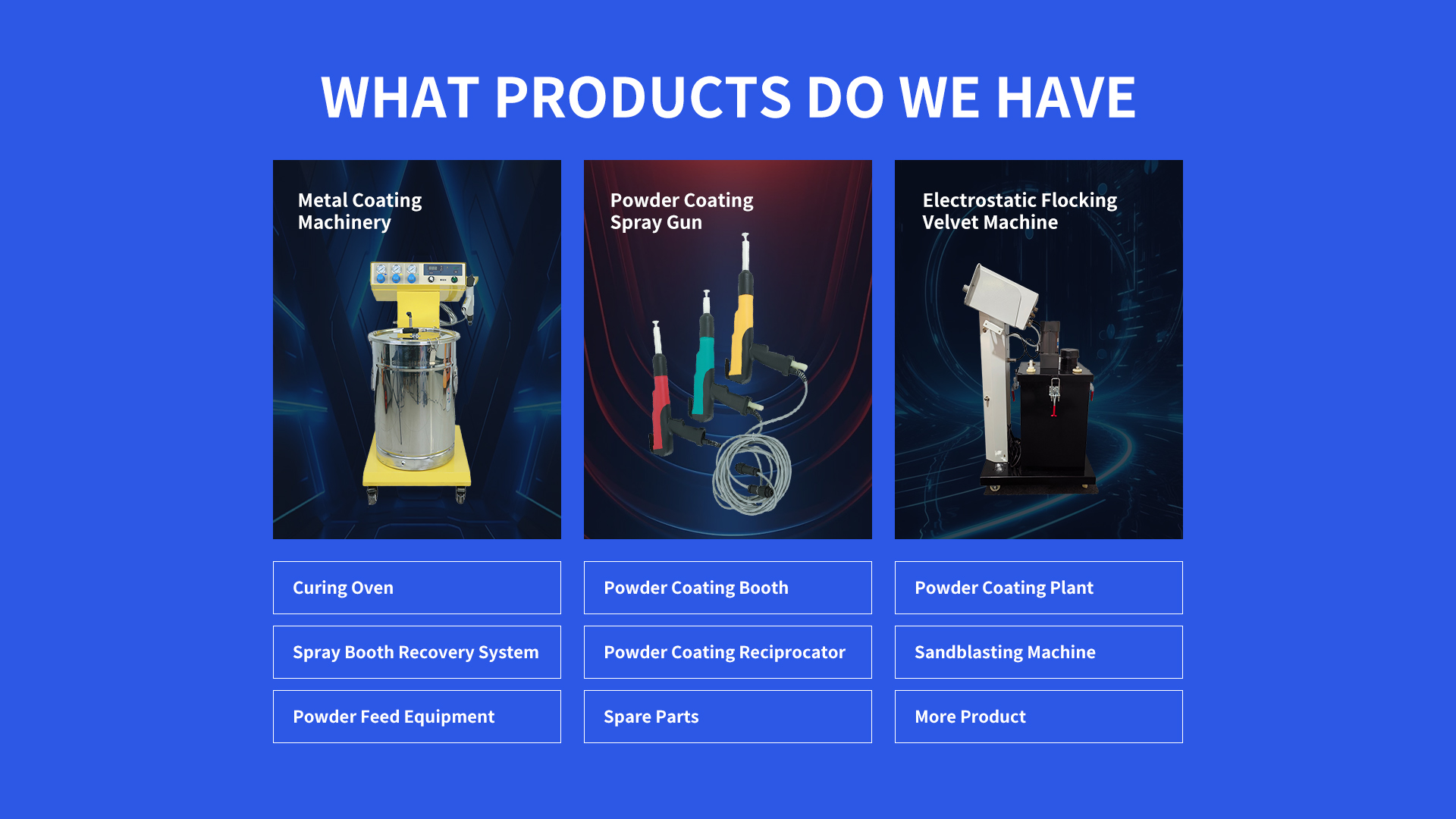

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com